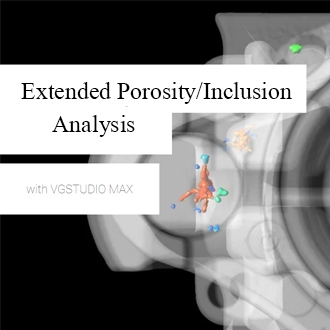

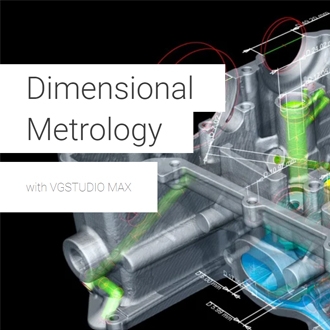

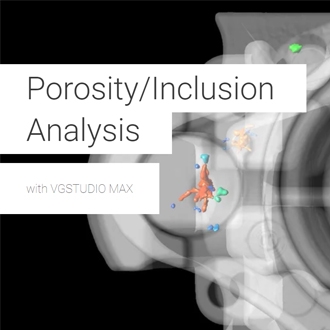

Porosity/Inclusion Analysis with VGStudioMax

Porosity/Inclusion Analysis with VGStudioMax

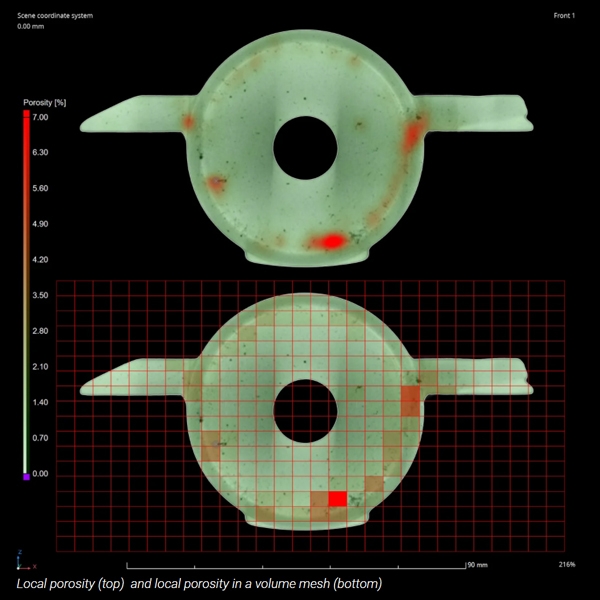

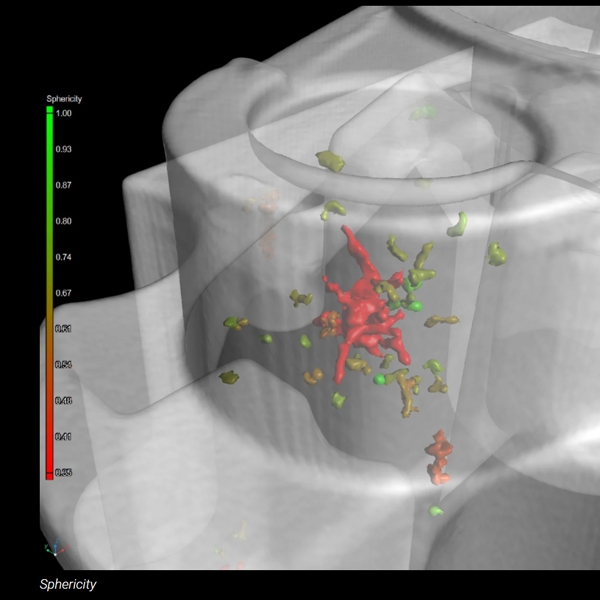

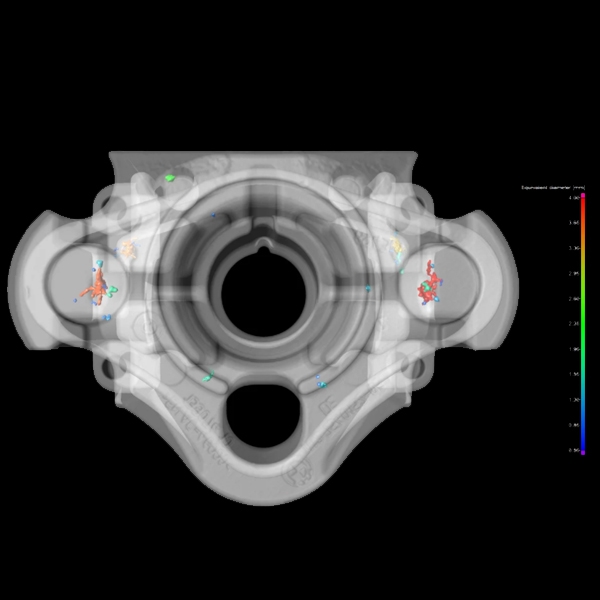

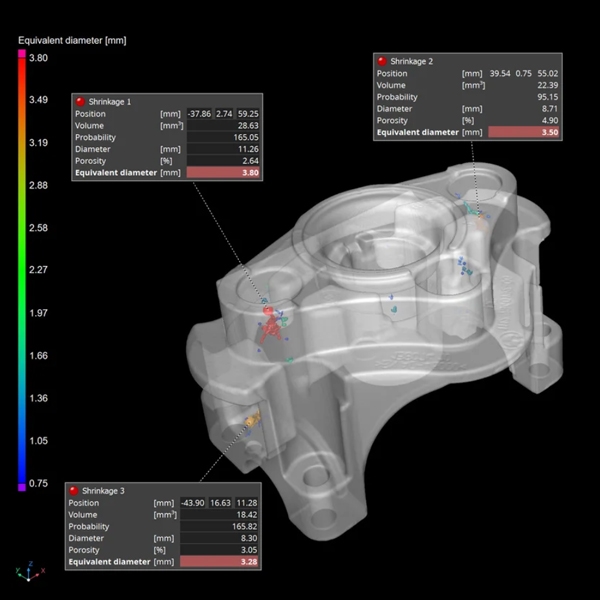

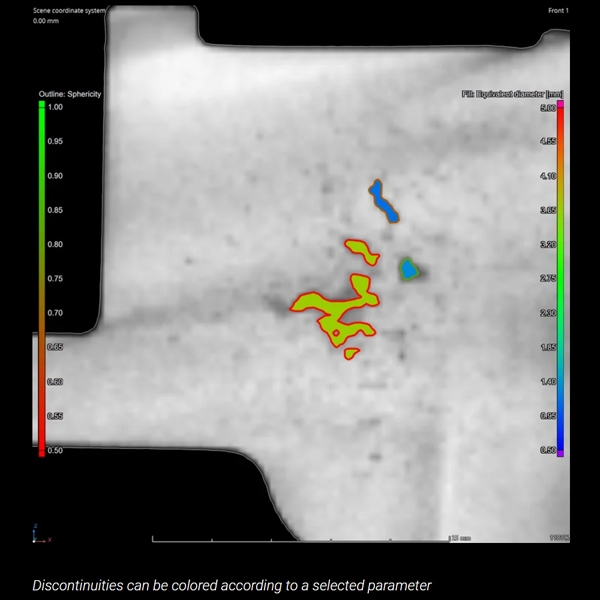

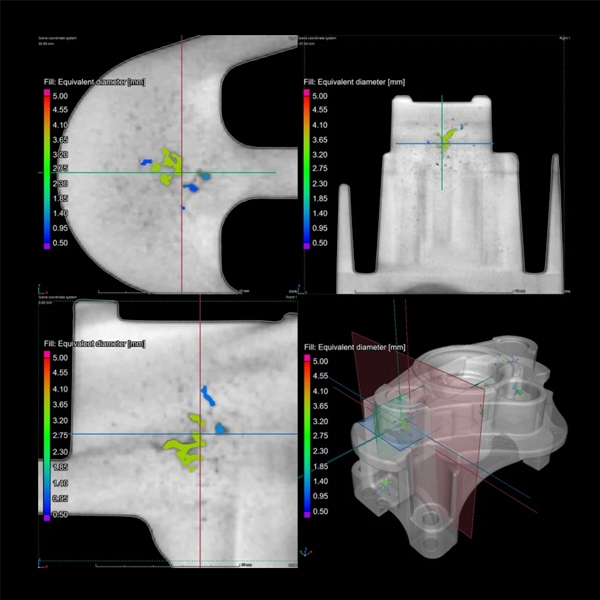

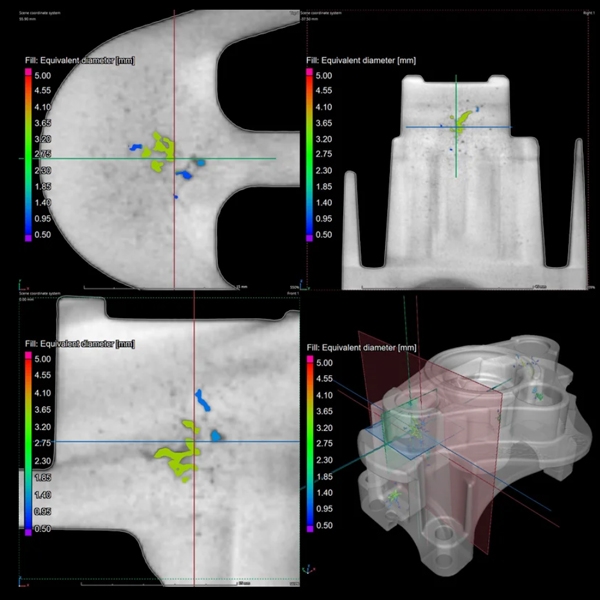

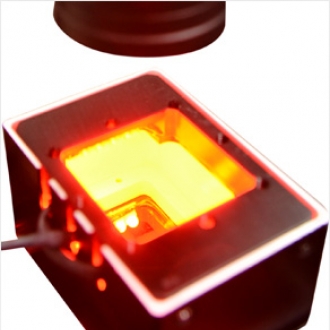

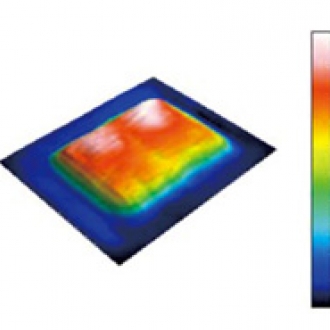

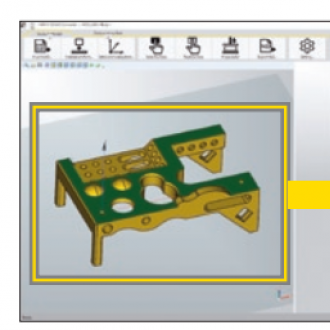

Discover what’s below the surface of your scanned parts. The porosity/inclusion analysis features in Volume Graphics software enable you to detect, characterize, and visualize porosity and inclusions in three dimensions using non-destructive testing (NDT).

Discover what’s below the surface of your scanned parts. The porosity/inclusion analysis features in Volume Graphics software enable you to detect, characterize, and visualize porosity and inclusions in three dimensions using non-destructive testing (NDT).

Porosity/Inclusion Analysis Features

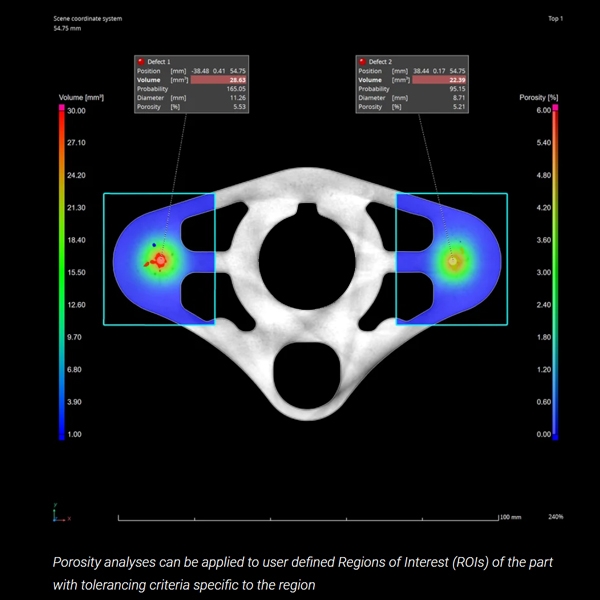

Locate pores, holes, and inclusions within parts and get detailed information on these discontinuities:- Detect, characterize, and visualize porosity in 2D and 3D using computed tomography.

- Distinguish between gas pores, shrinkage cavities, cracks, and inclusions of foreign material.

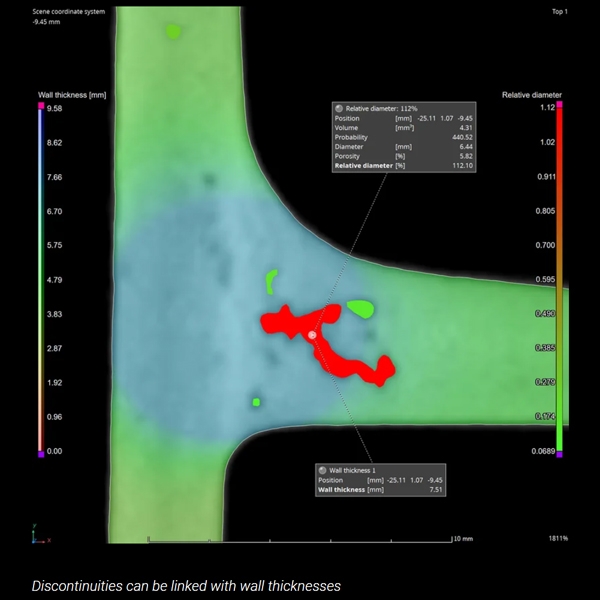

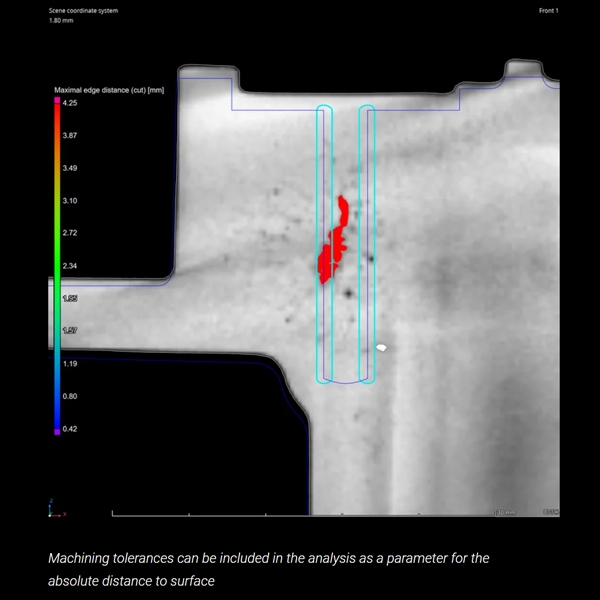

- Take wall thickness analyses and subsequent machining steps into account.

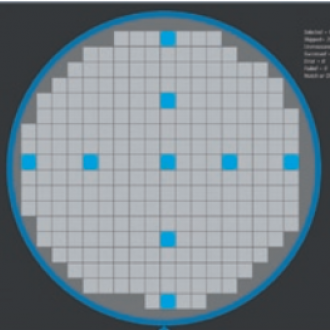

- Automatically quantify the surface size of discontinuities in 2D CT slice images in accordance to BDG Reference Sheet P 201/P 202. (Extended Porosity/Inclusion Analysis Module)

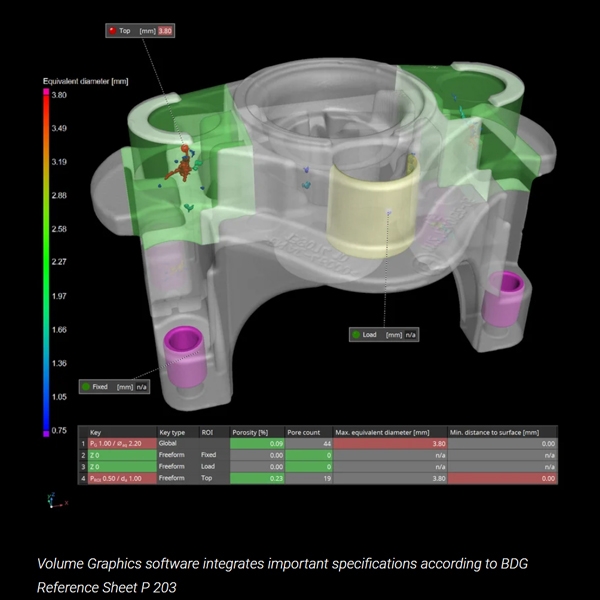

- Perform a 3D evaluation with regard to the most critical porosity parameters within functional areas of the part in accordance to BDG Reference Sheet P 203. (Extended Porosity/Inclusion Analysis Module)

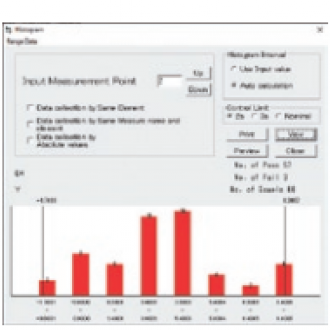

- Get results for later use in subsequent simulations.

- Use data in statistical evaluation software such as Q-DAS qs-STAT.

Global Porosity Parameters

Determine these global porosity parameters for the entire component:- Total pore volume

- Total material volume

- Total porosity

- Total surface of the pores

- Projected total area of all pores in any spatial direction

Related Products

-

New

NewH120 – High-Resolution Handhel…

-

New

NewSLK25 Laser Scanner – High Acc…

-

New

NewXC65Dx – Cross Laser Scanner f…

-

New

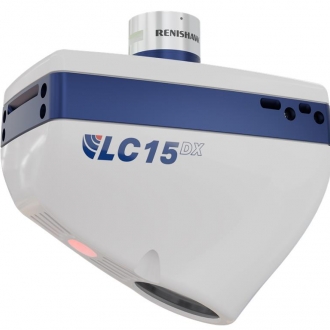

NewLC15Dx – The Highest-Accuracy …

-

New

NewL100NX CMM Laser Scanner

-

New

Digital Sight DS-100

-

New

NewFM-LXR

-

New

NewOPT SmartFlash-3020

-

New

NewDigital Microscope Inspectis U…

-

New

NewViTrox Smart Code Reader (XS S…

-

New

NewViTrox Smart Camera (XC Series…

-

New

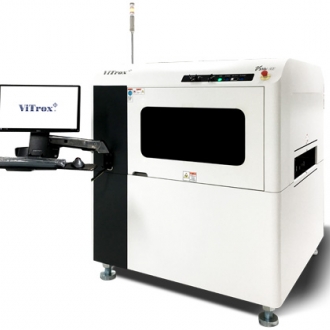

NewV510i DST

-

New

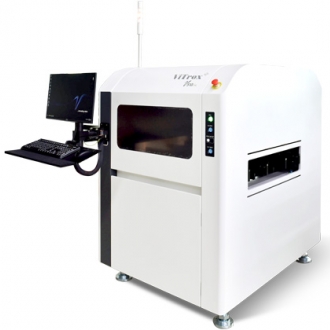

NewV510i ST

-

New

NewPX730i : Die Sorting & Vision …

-

New

NewWiX AI: Wafer Vision Inspectio…

-

New

NewV510i AOI for Advanced Packagi…

-

New

NewECLIPSE LV100N POL LED

-

New

NewLV100NDA LED

-

New

NewLV100ND LED

-

Hot

HotMD830M-C Digital Camera

-

New

NewMD830-C Digital Camera

-

New

NewMC2000 Digital Camera

-

New

NewMC500 Digital Camera

-

New

NewJX 2000 All-in-one Microscope …

-

New

NewDigital Sight DS-50M

-

New

NewDigital Sight DS-10

-

New

NewNew Evolution of Conformal Coa…

-

New

TMS2400 C Micro.View+ Compact

-

New

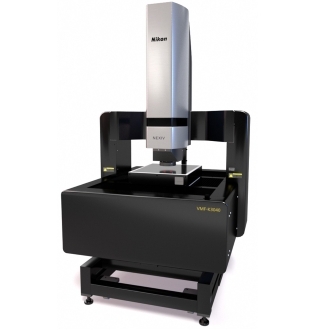

NewNEXIV VMZ-NWL200

-

HANDYSURF+

-

3R-JFIBER Movable tip industri…

-

Inspectis U30S

-

Hot

HotSMZ25 and SMZ18 Stereo zoom mi…

-

New

NewV9i Final Inspection (FI)

-

New

NewV9i Coating Inspection (CI)

-

V810i S2EX

-

V810i S2 XXL

-

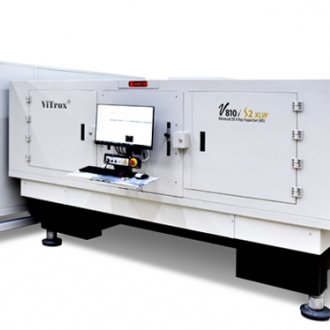

V810i S2 XLW

-

V810i S2 XLT

-

V810i S2 XLL

-

New

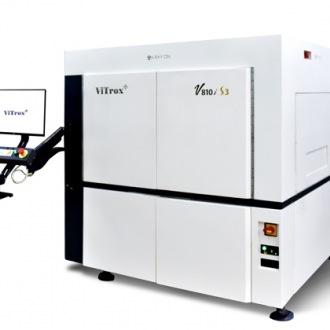

NewV810i S3

-

V510i DUO

-

V510i XXL

-

V510i 4.0

-

V510i XLW

-

V510i XL

-

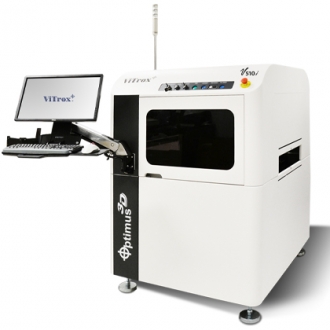

V510i Optimus 3D

-

New

NewV510i SE

-

New

NewV510i Optimus 3D (for Advanced…

-

V310i SE

-

V310i XXL

-

V310i XL

-

V310i

-

New

NewV310i Optimus (for Advanced Pa…

-

New

NewTR1000Si

-

New

NewTR3000i

-

New

NewTH3000i

-

New

NewVR20 Li

-

New

NewVR20 i

-

New

NewVR20i G2

-

New

NewBottom Carrier Tape Inspection

-

New

NewTape Seal Inspection

-

New

NewIn-Pocket Inspection

-

New

New3D & 5 Sided Inspection

-

New

NewMark, Lead & Package Inspectio…

-

New

NewOrientation Inspection

-

Hot

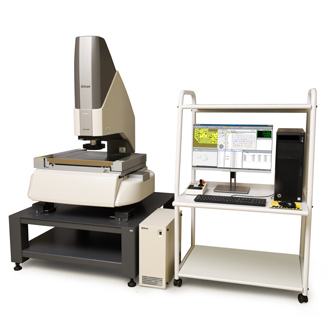

HotNEXIV VMZ-S3020

-

Hot

HotEDF/Stitching Express - Softwa…

-

Hot

HotXT V 130C

-

Hot

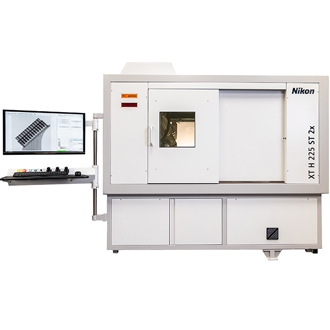

HotXT H 225 | Computed Tomography…

-

MCT225

-

SMZ445 & SMZ460 Stereoscopic Z…

-

Hot

HotEclipse MA100N

-

Fiber Composite Material Analy…

-

The Extended Porosity/Inclusio…

-

New

NewTmetric C20 3D camera

-

MAXIMA

-

CMM - CAMIO Software

-

Hot

HotNEXIV VMZ-S4540

-

Hot

HotNEXIV VMZ-S6555

-

Hot

HotiNEXIV VMA-2520

-

Hot

HotiNEXIV VMA-4540

-

Hot

HotiNEXIV VMA-6555

-

New

NewMountain Map - Software

-

New

New3D CAD Converter - Software

-

New

NewMapMeasure Pro - Software

-

New

NewImageFit QC- Software

-

Custom Fit - Software

-

PolyWorks | Modeler

-

New

NewPolyWorks | ReportLoop

-

PolyWorks | AR

-

Hot

HotNIS Software

-

BW-Series

-

Hot

HotMeasuring Microscope (MM-400)

-

Hot

HotMeasuring Microscope (MM-800)

-

Hot

HotE-Max software (DS-Type )

-

New

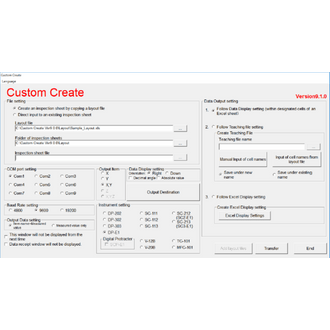

NewCustom Create

-

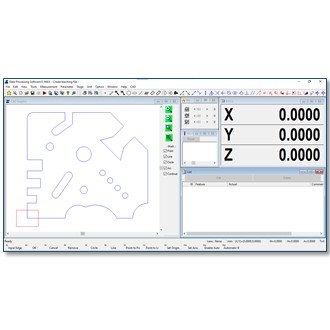

Data Processor (DP-E1A)

-

New

NewPolyWorks | PMI+Loop

-

PolyWorks | Talisman

-

PolyWorks | DataLoop

-

The Simple Solution for the Vi…

-

V-12B - 12" vertical optical c…

-

New

NewLaser Scanner ModelMaker H120

-

Hot

HotExtended Depth of Focus (EDF) …

-

Hot

HotTMS 2400

-

Hot

HotPolyWorks | Inspector

-

Hot

HotTMS 1400

-

New

NewSURFCOM NEX

-

SURFCOM CREST DX/SD

-

CONTOURECORD 1600G

-

Wall Thickness analysis with V…

-

FM Series

-

FV Series

-

FLV Series

-

FT-ZERO ARS-F SYSTEM

-

New

NewFR-XA

-

FR-X Series

-

LC-200R Series

-

FB-3000LC

-

New

NewFTC-AS Series

-

New

NewFTC-ASL Series

-

FTC-B255FS

-

FTC-D150A

-

New

NewFTM-AX

-

FTM-EVO

-

FTP-1AH

-

New

NewFTP-AX Series

-

New

NewFTP-MX Series

-

CUTTING WHEEL

-

HOT MOUNTING COMPOUNDS

-

SILICON CABIDE ABRASIVE PAPERS

-

EZ-DISK and MANETIC BASE FOR S…

-

WATER BASE DIAMOND SLURRIES, M…

-

HIGH PURITY ALUMINA (99.9%) an…

-

POLISHING CLOTHS

-

Photonic Fiber Optics Illumina…

-

Loupe

-

Dial Test Indicators

-

Signal Gauge SC-2A

-

Signal Gauge S-9

-

Signal Gauge S-7

-

Signal Gauge S-5

-

DIGITAL GAUGES -D/DL type

-

DIGITAL GAUGES -PND Type

-

DIGITAL GAUGES -DG type

-

Digital Counters

-

Dial Thickness Gauges

-

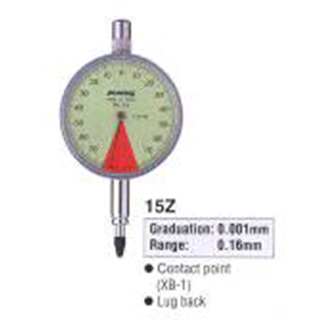

Dial Indicators

-

DIAL GAUGE STANDS & MAGNETIC S…

-

CALIPER GUAGE

-

HAYASHI_Korin KDR6142

-

HAYASHI LP-120 + HDR61WJ

-

TESTING STAND_M Series

-

TESTING STAND_K Series

-

TESTING STAND_KS-504H

-

TESTING STAND_KS-501H

-

TESTING STAND_KS-501E

-

PUSH-PULL GAUGES_MPC series

-

PUSH-PULL GAUGES_MPL series

-

PUSH-PULL GAUGES_MPS series

-

PUSH-PULL GAUGES_MP series

-

PUSH-PULL GAUGES_AP series

-

DIGITAL TORUGE CHECKER_DTC SER…

-

DIGITAL TORUGE CHECKER_ADT-C S…

-

DIGITAL FORCE GUAGES - ARFS SE…

-

DIGITAL FORCE GUAGES - ARF SER…

-

Cylinder Gauges

-

New

NewALTERA C

-

Hot

HotMicrendo Series

-

V20B - Large capacity vertical…

-

Hot

HotFlexiVision 100

-

Nominal/Actual Comparison with…

-

SMZ745 & SMZ745T Stereoscopic …

-

Hot

HotFlexilux Universal Borescope S…

-

Hot

HotFiberscope Series

-

Hot

HotEzyScope

-

Hot

HotMotorized Stepper Stage For In…

-

Quadra-Check Series

-

Hot

HotMotorised Stepper Stage For Up…

-

Hot

HotPro Scan lll

-

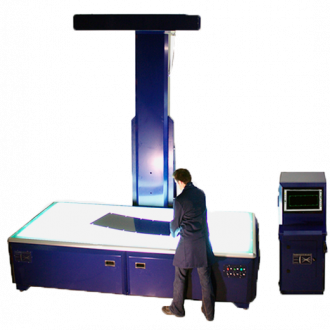

Large Sample Non Contact Profi…

-

Hot

HotNon Contact Flatness Measureme…

-

Hot

HotNon Contact Flatness Measureme…

-

RONDCOM NEX Rs α

-

PolyWorks | Reviewer

-

Laser Scanner XC65Dx-LS

-

Hot

HotEclipse MA200

-

Laser Scanner LC60Dx

-

Laser Scanner L100

-

Laser Scanner LC15Dx

-

Hot

HotMCAx S

-

Hot

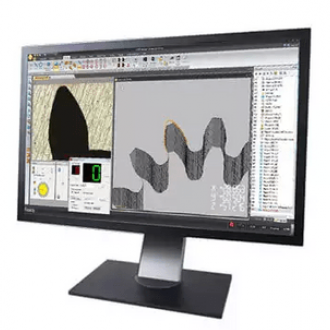

HotVGStudioMax Software

-

New

NewDigital Sight 1000

-

The Free Viewer App for Your 3…

-

Reverse Engineering with VGStu…

-

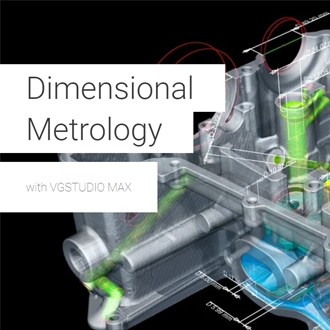

Coordinate Measurement Module …

-

New

NewNew X-ray CT system with enhan…

-

Hot

HotXT V 160

-

Hot

HotE-MAX D Type

-

Hot

HotStereo Microscope (Paralell) S…

-

New

NewNEXIV VMF-K6555

-

NEXIV VMZ-H3030

-

Hot

HotALTERA S

-

SMZ-2 Stereoscopic Zoom Micros…

-

Hot

HotPorosity/Inclusion Analysis wi…

-

SCANTEK5

-

Hot

HotData processor (DP-E1A)

-

APDIS MV4x0 Laser Radar

-

Hot

HotALTERA M

-

New

NewWELDinspect 4K

-

New

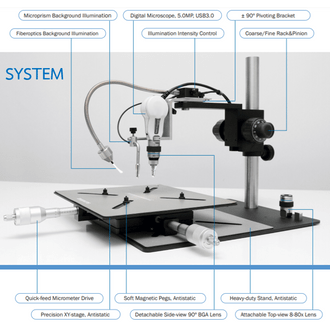

NewBGA Inspection System

-

Digimicro MF-501

-

Hot

HotEclipse LV150N

-

Eclipse LV100ND

-

Eclipse LV100N POL

-

Eclipse L200N Series

-

Eclipse L300N Series

-

Digimicro MF-1001

-

Hot

HotNEXIV AutoMeasure Software

-

New

NewCMM-Manager for iNEXIV Softwar…

-

DIGITAL FORCE GUAGES - ARF ser…

-

New

NewNEXIV Remote Control SDK

-

TOUCH50

-

ALTERA SL

-

New

NewNEXIV VMF-K3020