XC65Dx – Cross Laser Scanner for Complex Surface Inspection

The XC65Dx Cross Scanner integrates three laser stripe scanners into a single sensor, positioned 120 degrees apart to observe the part from three different angles simultaneously.

This configuration enables the XC65Dx to capture the same amount of data in one scan that a traditional line scanner would require three separate scans to acquire. This makes it particularly effective for inspecting features such as slots, holes, and grooves, as well as components with large or highly complex surfaces.

The XC65Dx is widely used in the automotive industry for:

-

Body-in-White (BIW) inspection

-

Gap & Flush analysis

-

Driveline casting inspection

The Long Standoff version of the XC65Dx maintains all the advantages of the original model while excelling in scanning hard-to-reach or obstructed areas. With an extended measurement distance of up to 170 mm (7.1"), it allows optimal access to cavity surfaces of BIW structures or lets the scanner operate above clamps and fixtures.

For these reasons, the XC65Dx is commonly deployed on horizontal-arm CMMs within the automotive sector.

Technical Specifications

| Specification | Value |

|---|---|

| Scanner Type | Cross |

| Points/Second (Cross Mode) | 3 × 25,000 |

| Points/Second (Single Line Mode) | 75,000 |

| Scan Rate | 75 Hz |

| Points per Line | 900 |

Related Products

-

New

NewH120 – High-Resolution Handhel…

-

New

NewSLK25 Laser Scanner – High Acc…

-

New

NewXC65Dx – Cross Laser Scanner f…

-

New

NewLC15Dx – The Highest-Accuracy …

-

New

NewL100NX CMM Laser Scanner

-

New

Digital Sight DS-100

-

New

NewFM-LXR

-

New

NewOPT SmartFlash-3020

-

New

NewDigital Microscope Inspectis U…

-

New

NewViTrox Smart Code Reader (XS S…

-

New

NewViTrox Smart Camera (XC Series…

-

New

NewV510i DST

-

New

NewV510i ST

-

New

NewPX730i : Die Sorting & Vision …

-

New

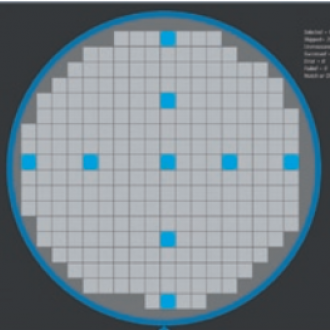

NewWiX AI: Wafer Vision Inspectio…

-

New

NewV510i AOI for Advanced Packagi…

-

New

NewECLIPSE LV100N POL LED

-

New

NewLV100NDA LED

-

New

NewLV100ND LED

-

Hot

HotMD830M-C Digital Camera

-

New

NewMD830-C Digital Camera

-

New

NewMC2000 Digital Camera

-

New

NewMC500 Digital Camera

-

New

NewJX 2000 All-in-one Microscope …

-

New

NewDigital Sight DS-50M

-

New

NewDigital Sight DS-10

-

New

NewNew Evolution of Conformal Coa…

-

New

TMS2400 C Micro.View+ Compact

-

New

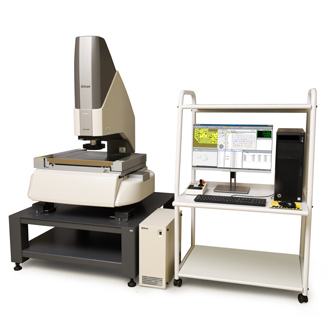

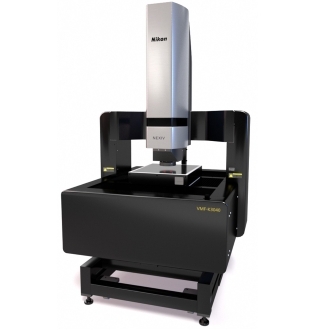

NewNEXIV VMZ-NWL200

-

HANDYSURF+

-

3R-JFIBER Movable tip industri…

-

Inspectis U30S

-

Hot

HotSMZ25 and SMZ18 Stereo zoom mi…

-

New

NewV9i Final Inspection (FI)

-

New

NewV9i Coating Inspection (CI)

-

V810i S2EX

-

V810i S2 XXL

-

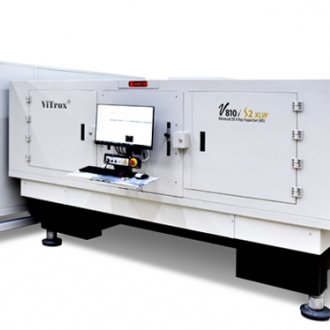

V810i S2 XLW

-

V810i S2 XLT

-

V810i S2 XLL

-

New

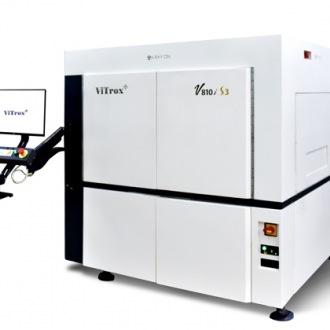

NewV810i S3

-

V510i DUO

-

V510i XXL

-

V510i 4.0

-

V510i XLW

-

V510i XL

-

V510i Optimus 3D

-

New

NewV510i SE

-

New

NewV510i Optimus 3D (for Advanced…

-

V310i SE

-

V310i XXL

-

V310i XL

-

V310i

-

New

NewV310i Optimus (for Advanced Pa…

-

New

NewTR1000Si

-

New

NewTR3000i

-

New

NewTH3000i

-

New

NewVR20 Li

-

New

NewVR20 i

-

New

NewVR20i G2

-

New

NewBottom Carrier Tape Inspection

-

New

NewTape Seal Inspection

-

New

NewIn-Pocket Inspection

-

New

New3D & 5 Sided Inspection

-

New

NewMark, Lead & Package Inspectio…

-

New

NewOrientation Inspection

-

Hot

HotNEXIV VMZ-S3020

-

Hot

HotEDF/Stitching Express - Softwa…

-

Hot

HotXT V 130C

-

Hot

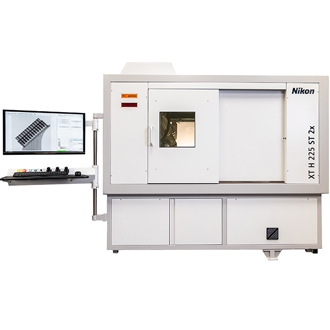

HotXT H 225 | Computed Tomography…

-

MCT225

-

SMZ445 & SMZ460 Stereoscopic Z…

-

Hot

HotEclipse MA100N

-

Fiber Composite Material Analy…

-

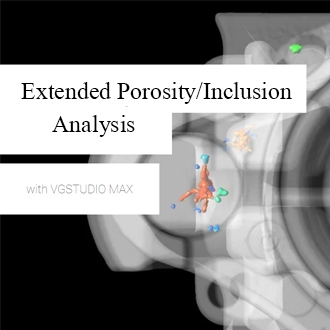

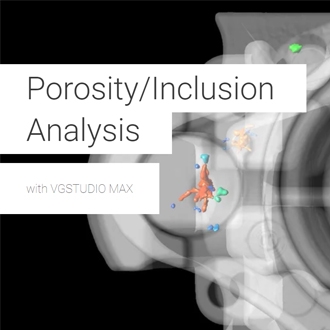

The Extended Porosity/Inclusio…

-

New

NewTmetric C20 3D camera

-

MAXIMA

-

CMM - CAMIO Software

-

Hot

HotNEXIV VMZ-S4540

-

Hot

HotNEXIV VMZ-S6555

-

Hot

HotiNEXIV VMA-2520

-

Hot

HotiNEXIV VMA-4540

-

Hot

HotiNEXIV VMA-6555

-

New

NewMountain Map - Software

-

New

New3D CAD Converter - Software

-

New

NewMapMeasure Pro - Software

-

New

NewImageFit QC- Software

-

Custom Fit - Software

-

PolyWorks | Modeler

-

New

NewPolyWorks | ReportLoop

-

PolyWorks | AR

-

Hot

HotNIS Software

-

BW-Series

-

Hot

HotMeasuring Microscope (MM-400)

-

Hot

HotMeasuring Microscope (MM-800)

-

Hot

HotE-Max software (DS-Type )

-

New

NewCustom Create

-

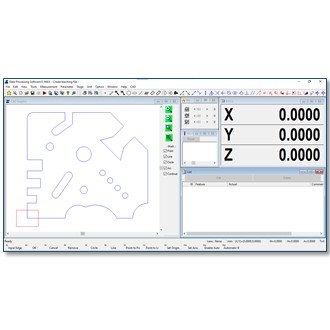

Data Processor (DP-E1A)

-

New

NewPolyWorks | PMI+Loop

-

PolyWorks | Talisman

-

PolyWorks | DataLoop

-

The Simple Solution for the Vi…

-

V-12B - 12" vertical optical c…

-

New

NewLaser Scanner ModelMaker H120

-

Hot

HotExtended Depth of Focus (EDF) …

-

Hot

HotTMS 2400

-

Hot

HotPolyWorks | Inspector

-

Hot

HotTMS 1400

-

New

NewSURFCOM NEX

-

SURFCOM CREST DX/SD

-

CONTOURECORD 1600G

-

Wall Thickness analysis with V…

-

FM Series

-

FV Series

-

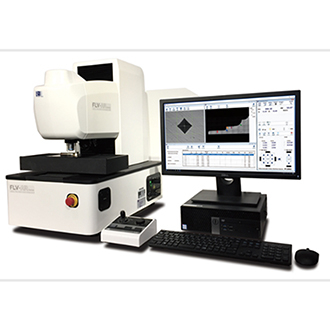

FLV Series

-

FT-ZERO ARS-F SYSTEM

-

New

NewFR-XA

-

FR-X Series

-

LC-200R Series

-

FB-3000LC

-

New

NewFTC-AS Series

-

New

NewFTC-ASL Series

-

FTC-B255FS

-

FTC-D150A

-

New

NewFTM-AX

-

FTM-EVO

-

FTP-1AH

-

New

NewFTP-AX Series

-

New

NewFTP-MX Series

-

CUTTING WHEEL

-

HOT MOUNTING COMPOUNDS

-

SILICON CABIDE ABRASIVE PAPERS

-

EZ-DISK and MANETIC BASE FOR S…

-

WATER BASE DIAMOND SLURRIES, M…

-

HIGH PURITY ALUMINA (99.9%) an…

-

POLISHING CLOTHS

-

Photonic Fiber Optics Illumina…

-

Loupe

-

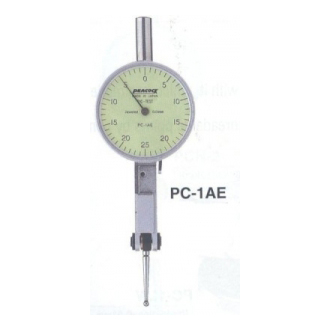

Dial Test Indicators

-

Signal Gauge SC-2A

-

Signal Gauge S-9

-

Signal Gauge S-7

-

Signal Gauge S-5

-

DIGITAL GAUGES -D/DL type

-

DIGITAL GAUGES -PND Type

-

DIGITAL GAUGES -DG type

-

Digital Counters

-

Dial Thickness Gauges

-

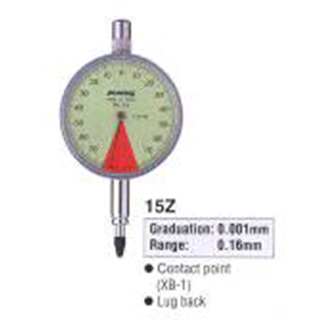

Dial Indicators

-

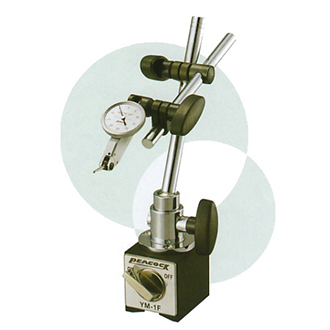

DIAL GAUGE STANDS & MAGNETIC S…

-

CALIPER GUAGE

-

HAYASHI_Korin KDR6142

-

HAYASHI LP-120 + HDR61WJ

-

TESTING STAND_M Series

-

TESTING STAND_K Series

-

TESTING STAND_KS-504H

-

TESTING STAND_KS-501H

-

TESTING STAND_KS-501E

-

PUSH-PULL GAUGES_MPC series

-

PUSH-PULL GAUGES_MPL series

-

PUSH-PULL GAUGES_MPS series

-

PUSH-PULL GAUGES_MP series

-

PUSH-PULL GAUGES_AP series

-

DIGITAL TORUGE CHECKER_DTC SER…

-

DIGITAL TORUGE CHECKER_ADT-C S…

-

DIGITAL FORCE GUAGES - ARFS SE…

-

DIGITAL FORCE GUAGES - ARF SER…

-

Cylinder Gauges

-

New

NewALTERA C

-

Hot

HotMicrendo Series

-

V20B - Large capacity vertical…

-

Hot

HotFlexiVision 100

-

Nominal/Actual Comparison with…

-

SMZ745 & SMZ745T Stereoscopic …

-

Hot

HotFlexilux Universal Borescope S…

-

Hot

HotFiberscope Series

-

Hot

HotEzyScope

-

Hot

HotMotorized Stepper Stage For In…

-

Quadra-Check Series

-

Hot

HotMotorised Stepper Stage For Up…

-

Hot

HotPro Scan lll

-

Large Sample Non Contact Profi…

-

Hot

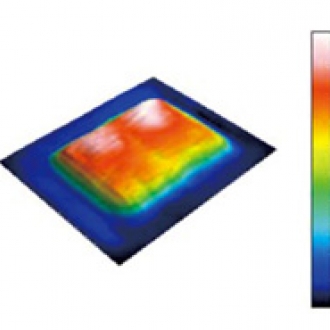

HotNon Contact Flatness Measureme…

-

Hot

HotNon Contact Flatness Measureme…

-

RONDCOM NEX Rs α

-

PolyWorks | Reviewer

-

Laser Scanner XC65Dx-LS

-

Hot

HotEclipse MA200

-

Laser Scanner LC60Dx

-

Laser Scanner L100

-

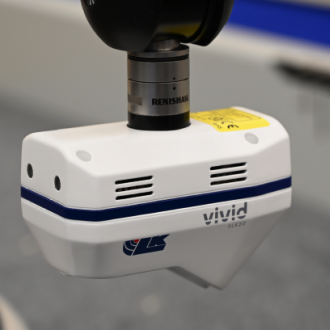

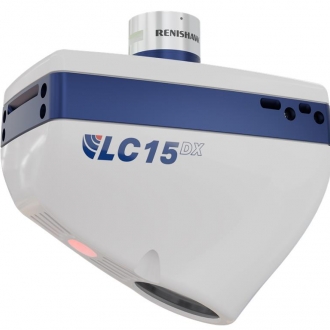

Laser Scanner LC15Dx

-

Hot

HotMCAx S

-

Hot

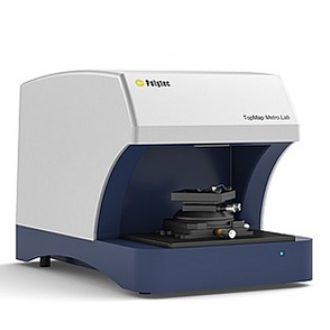

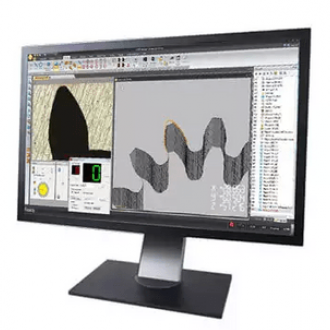

HotVGStudioMax Software

-

New

NewDigital Sight 1000

-

The Free Viewer App for Your 3…

-

Reverse Engineering with VGStu…

-

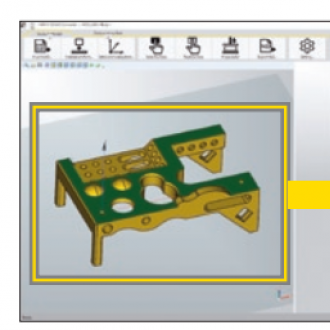

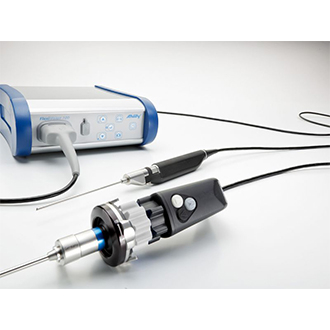

Coordinate Measurement Module …

-

New

NewNew X-ray CT system with enhan…

-

Hot

HotXT V 160

-

Hot

HotE-MAX D Type

-

Hot

HotStereo Microscope (Paralell) S…

-

New

NewNEXIV VMF-K6555

-

NEXIV VMZ-H3030

-

Hot

HotALTERA S

-

SMZ-2 Stereoscopic Zoom Micros…

-

Hot

HotPorosity/Inclusion Analysis wi…

-

SCANTEK5

-

Hot

HotData processor (DP-E1A)

-

APDIS MV4x0 Laser Radar

-

Hot

HotALTERA M

-

New

NewWELDinspect 4K

-

New

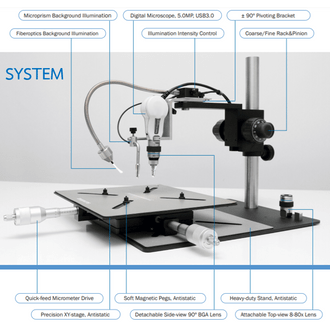

NewBGA Inspection System

-

Digimicro MF-501

-

Hot

HotEclipse LV150N

-

Eclipse LV100ND

-

Eclipse LV100N POL

-

Eclipse L200N Series

-

Eclipse L300N Series

-

Digimicro MF-1001

-

Hot

HotNEXIV AutoMeasure Software

-

New

NewCMM-Manager for iNEXIV Softwar…

-

DIGITAL FORCE GUAGES - ARF ser…

-

New

NewNEXIV Remote Control SDK

-

TOUCH50

-

ALTERA SL

-

New

NewNEXIV VMF-K3020